US Army Uniform Profile

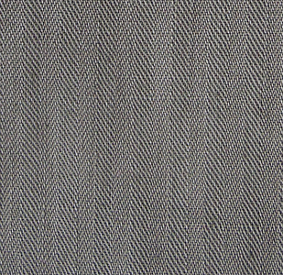

Two-Piece Herringbone Twill Suit

(1941-1942)

Point or touch each image for descriptions

Two-Piece Herringbone Twill Suit (1941-42)

Introduction

The familiar herringbone twill clothing of WW2 came into being as a result of an Army program to develop suitable clothing for mechanized troops and the desire for a practical and economical garment for all troops to wear during field training exercises. In order to be successful, such a project would depend heavily on the development of a fabric that was rugged and durable enough to withstand the intended use. Herringbone twill was the fabric that emerged and would eventually be used to fashion a number of different uniforms, but its first application was in conjunction with the development of a versatile one‐piece coverall. With the expansion of mechanized and armored units during the 30s, a durable, appropriately colored garment was needed for tank personnel and men working with other types of vehicles. In 1936 an evaluation was conducted by the Infantry Board that compared a one‐piece mechanic's suit adopted by the Air Force (Suit, Mechanic's Aircraft, One-piece, Type B‐1) and the standard Army one‐piece denim working suit (Suits, Working, One‐Piece, Specification QMC 6‐225, 1933). The B-1 coveralls were made in olive drab herringbone twill fabric, while the Army's one‐piece suit in use at the time was made in indigo blue denim. After testing was concluded in the fall of 1936, the Army determined the B‐1 mechanic's suit to be superior to the blue denim type and the Chief of the Infantry recommended that a suit similar in design and color to the B‐1 be adopted for mechanized troops.

During the following year, the War Department Uniform Board also considered the adoption of a one‐piece suit. At the time, National Guard commanders ordered the use of denim chore clothing in lieu of traditional wool and cotton service uniforms for field exercises in order to save on laundry expenses and replacement costs for these more expensive garments. As a result, commanders requested a one‐piece coverall designed specifically for use during field exercises. Additional support was given to this idea because the development of protective clothing for chemical warfare was moving in the direction of a one‐piece design and adopting such a suit could potentially fulfill a dual purpose. At this time, an official recommendation was submitted by the National Guard Bureau for the approval of an olive drab or khaki one‐piece suit.

The Chief of Infantry's recommendation for a B‐1 style suit for the Armored Forces was considered and approved by the Quartermaster Corps Technical Committee in the spring the 1937. Shortly thereafter, the Office of the Quartermaster General assigned the Philadelphia Depot the tasks of developing a pattern for the new uniform and finding a suitable fabric that was of the proper color and durability. In early 1938, the fabric used to line the enlisted man's overcoat (Specification QMC 6-237, Cloth, Cotton, Lining for Overcoats, 1936) was selected for use, but would be made using a herringbone weave instead (Cloth, Cotton, Herringbone Twill, Specification QMC 6‐261, 1938). This new fabric would raise the cost of the new suit by approximately 50% over the old denim type. Because of this significant increase in cost, the decision on whether to adopt the herringbone twill suit was referred directly to the War Department. It was on 29 April 1938 that the War Department gave its approval and the Quartermaster moved forward with procurement of the herringbone twill fabric and production of the one‐piece suit.

In the end, the Army's one‐piece suit was very similar to the Air Force's B‐1 type with there being only slight differences in the detail of the design and weave of the HBT fabric. Both suits were not much different from commercial one‐piece work garments of the time nor from the blue denim type they superseded other than for the color and type fabric used in construction. When viewed up close, the fabric's alternating rows of diagonal weave form a fishbone pattern that gives herringbone twill its name. From a distance, the alternating rows of twill weave produce a prominent vertical striping effect that's instantly recognizable. The fabric became a staple being used to manufacture Army, Navy, and Marine Corps work and combat uniforms for over a decade and was often simply abbreviated as HBT.

By the fall of 1938, enough HBT fabric had been delivered to the Philadelphia Depot allowing construction of the new one‐piece suits to begin. The nomenclature and specification were established as follows: Suits, Working, One‐Piece (Herringbone Twill), Federal Specification BBB‐S‐786, dated 19 December 1938. Items that were useful to the Government outside of the War Department received a federal specification designation. In this case, the one‐piece suit was used by other departments of the Federal Government that maintained motor pools. Mass procurement of one‐piece HBT suits was intentionally delayed allowing stocks of the old blue denim type to be used up. As a result, it wasn't until the fall of 1940 that the one-piece HBT suit was procured from commercial manufacturers in large quantities.

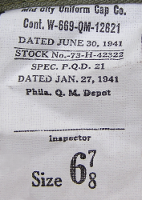

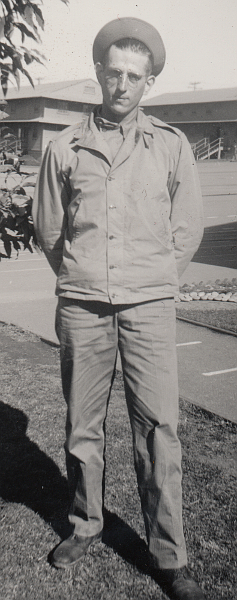

In the spring of 1941, doctrine concerning the use of the HBT uniforms changed in response to increased procurement needs brought about by the rapid expansion of the Army. Though, early on, the one‐piece suit was utilized as a field training coverall, it was soon realized that with a war coming this practice wouldn't be feasible on a mass scale. This was because the one‐piece suit was relatively complicated to manufacture, and its procurement channels were limited to contractors with experience making this type of garment. In response, it was announced that the one‐piece suit would only be issued to mechanics and armored forces personnel and all other troops would be issued a two‐piece suit. The idea was that a two‐piece suit would be easier to mass produce where a wider range of contractors could contribute. This idea was further leveraged by using existing designs for the trousers and hat for which there were already experienced contractors. The trousers used the same pattern as the khaki cotton trousers (Trousers, Cotton, Khaki; Specification QMC 6-254 dated 8 November 1937) and the hat used the same pattern as the cotton field hat (Hats, Field, Cotton; Specification PQD 21 dated 27 January 1941) except both would also now be made in HBT. Unlike the trousers, the HBT jacket was an entirely new design that was patterned similar to a western style denim jacket of the period. The two‐piece HBT suit would replace the denim working coat and trousers as a work and chore uniform and would also be used for field training exercises. Around this same time, a HBT cap (Cap, Herringbone Twill; Specification PQD 18B dated 8 April 1941) was introduced to be issued to men who received the one‐piece suit.

Development of Army uniforms was extremely active between 1938 and 1942. It was a time when uniforms were modernized after most had not seen any significant change for several decades. This was also a time when many completely new uniform designs were introduced. The modernization program was initiated in response to the European and Sino‐Japanese wars and the likelyhood that the US would find itself involved in a global war requiring troops to be stationed around the world in varying climates and terrain. Changes in military tactics also required the use of specialized units, such as parachute, armored, ranger, etc., each with their own particular clothing requirements. During this time, new materials and design concepts popular in the civilian market were introduced into Army Uniforms. Though designs from this period considered the specific needs of the troops that were to wear them, they also borrowed heavily from similar purpose civilian designs due to the lack of any previous military application. This approach made for some very interesting and classic designs, though sometimes they would turn out to be impractical and uneconomical in wartime. The two‐piece HBT outfit was a text‐book example of a uniform introduced during this interesting developmental time period. Though good looking and sufficiently durable, neither the jacket nor trousers were particularly useful work garments considering their intended purpose. This is especially apparent when compared to previous designs and standard work garments of the time. As noted, the two‐piece HBT uniform was also used for field training exercises, another role for which it wasn't especially well suited for. As was the case with many garments developed by the Army during this time, the jacket was overabundant with fine detail, such as pleated pockets and shoulders, shirt style cuffs, and a bottom waistband with take‐up straps. These features tended to add to cost and complexity rather than to practical utility or ergonomics related to the garment's intended use. For example, while expanding pocket pleats are a useful feature, the benefits are diminished substantially when the pocket itself is far too small for many practical applications. Furthermore, the type of complexity designed into the early HBT jacket wasn't conducive to maximizing production during a crisis. Similarly, the trousers were essentially a standard civilian cut pattern with internally hung pockets, a design that wasn't the norm for any type of work garment. These kinds of shortcomings plagued many of the uniforms developed during this period though generally they ended up being overall improvements over the designs they replaced.

By the summer of 1942 work had begun on a tropical combat uniform for use in upcoming operations in the Southwest Pacific area. This endeavor led to the development of the one-piece jungle suit, which used the same 8.5‐ounce HBT fabric as did the standard one and two‐piece suits, except the material had a printed camouflage pattern on it. Though research and development into a fabric that would be optimal for tropical environments occurred throughout the War, production limitations prevented the implementation of a uniform made in such a material until after the end of hostilities. Thus, HBT became the de facto fabric for hot and tropical weather combat use. It was originally intended that the one‐piece jungle suit be a standard issue item for troops operating in tropical environments, but for a number of reasons the one‐piece design and camouflage pattern proved to be unsatisfactory. With these developments, the two‐piece HBT suit was elevated into the primary role of hot and tropical weather combat uniform where it replaced both the jungle suit and cotton khaki uniform as standard issue.

Around this same time there was an urgent need for uniforms to clothe the large influx of men into the Army, and it was recognized that HBT suits had to be simplified in order to expedite the manufacturing process. In the fall of 1942 work began on redesigning and simplifying construction of the two‐piece suit. The one‐piece jungle suit had been designed with two large, expanding cargo pockets on the chest and similar pockets on the outside of each thigh. This pocket arrangement was carried over to the new two-piece HBT suit adding much needed utility to an outfit that would now assume a combat role. In addition to the new pocket configuration, the jacket was further simplified by eliminating the shirt‐style cuffs and waistband for simple hems. The trousers became much easier to produce by having the five internally hung pockets and double welt openings eliminated in favor of the two much simpler patch cargo pockets. Even though there would continue to be minor changes made to the two‐piece HBT suit throughout the War, including a significant darkening of the color in 1943, the basic design adopted at the end of 1942 would be the most common and remain intact until 1945. In addition to changes to the jacket and trousers, the full brimmed hat was replaced by a short billed cap that had previously only been issued with the one‐piece suit. It should be noted here that collectors and historians commonly refer to the two‐piece HBT suit developed in 1941 that is discussed and pictured in this Uniform Profile as the "first pattern" or sometimes the "M‐1941" type. This article will also use these terms in reference to the first two‐piece suit developed in 1941.

Once the new style jackets, trousers, and caps came into the supply system they mixed freely with the first pattern. Initially no distinction was made between the old and new outfits and the stock numbers for the new jacket and trousers remained unchanged from the old. In fact, it is not uncommon for period photos to show a mixture of different jacket/trousers/hat/cap combinations being worn. For example, a first pattern jacket being worn with cargo pocket trousers or vice versa; light shade garments with dark shade garments; or the old‐style hat with a newer cargo pocket outfit, etc. Eliminating the waistband allowed the new jacket to be tucked inside the trousers or worn on the outside like the first pattern jacket. However, once the new jackets appeared, they were usually worn tucked inside the trousers unless ventilation was needed in hot conditions. Usually, the way the jacket was worn was determined by the commanding officer. Without a distinction between the old and new types, the first pattern jacket was worn tucked inside trousers as well. Because first pattern jackets were not intended to be worn this way, surviving examples are sometimes found with the waistband straps and buckles removed, likely done to make wear inside the trousers more comfortable. Like most field clothing and equipment, HBT suits could be worn by officers as well as enlisted men. While HBT suits were part of the enlisted man's basic clothing allowance, they were an optional purchase for officers when assigned to a theater of operations.

Another important variation of the two‐piece HBT suit involved the incorporation of gas protection features beginning with the new cargo pocket types introduced in late 1942. This involved adding a flap of material behind the front opening of the jacket and the fly of the trousers that could be buttoned across the opening to keep blistering agents away from the skin. Buttons for attaching a protective hood were also added to the back of the jacket's collar. Garments made with these features included the word "Special" in their nomenclature. Special garments were intended to be impregnated with a solution making them more resistant gas vapors. Initially, some HBT suits were made with the gas protection features and were designated for overseas use, while others were made without them and were to be issued for use in the continental US. By the summer of 1943, however, the gas protection features were built into all new production two‐piece HBT suits. Once the decision was made to standardize the gas protection features, some older garments, including the first pattern two‐piece HBT suits discussed here, were retrofitted with these features.

Headgear

There were several types of headgear that were routinely worn with the first pattern two‐piece HBT suit. The most important of these was the Herringbone Twill Hat, which was integral to the uniform and was issued along with it as part of the enlisted man's basic clothing allowance. This hat used the same pattern and specification number as the Cotton Field Hat (Hats, Field, Cotton, Specification No. PQD No. 21, dated 27 January 1941), which was amended in June 1941 to include the Herringbone Twill Hat. Though the hat had a wide, heavy brim around its entire circumference, it was still soft enough so that it could be folded and carried in a pocket. It had a four gore crown with each segment having a small metal grommet in the center to provide ventilation. The flexible brim, which could be flipped up or down, allowed the hat to be worn several different ways. Though the prescribed manner of wear was with the entire brim in the down position, photos show GIs wearing the hat with the front brim up, rear brim up, or the entire brim up. Much to the annoyance of commanding officers, some GIs used the hat to make their own personal fashion statements by wearing their favorite brim position with the hat cocked in an unauthorized position on the head.

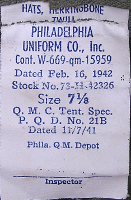

In late 1941, an improved HBT hat was authorized that featured additional vent holes (Hats, Herringbone Twill, Specification No. PQD 21B, dated 7 November 1941). Each segment of the crown now had two venting grommets bringing the total on the hat from four to eight. In the fall of 1942, at the same time the two‐piece HBT suit was redesigned with cargo pockets, the HBT hat was replaced by the herringbone twill cap. The cap, previously approved in the spring of 1941 and only issued to men who received the one‐piece HBT suit, provided a neater appearance than did the hat and was almost half the cost. Since large quantities of HBT hats remained in the supply system its status was changed to Limited Standard. This meant that remaining stocks of the hat would continue to be issued until exhausted, but further procurement was terminated. Final procurement of HBT hats occurred in May 1942 and beginning in October 1942 consisted solely of caps. Once caps entered the supply chain they mixed freely with the older hats as did the old and new type jackets and trousers. As the transition between old and new uniforms occurred, soldiers could be issued any combination of old and new style jackets, trousers, and either the hat or cap.

When the two‐piece HBT suit was used for field training exercises or campaigning, other types of headgear were often prescribed for wear. Most notably, the M‐1917‐A1 steel helmet or the new pot shaped M‐1 helmet were worn. The M‐1917‐A1 helmet was an updated version of the saucer‐shaped WW1 helmet but with an improved liner. The M‐1917‐A1 was still the predominant helmet in use when the two‐piece HBT suit first arrived on the scene. Shortly thereafter, the M‐1 helmet became standard issue. The M‐1 was a two-piece system consisting of a pot-shaped steel shell and a removable liner that was molded to fit inside the shell. The removable liner was considered a separate piece of headgear in its own right. Typically, the steel shell was only issued in theater of operations, combat zones, or for simulated combat. Otherwise, the lighter, but less protective, liner was worn by itself. There were two main types of M‐1 helmet liner produced. An early type made of cloth covered fiber composition similar in construction to a pith helmet, and a later type made of resin impregnated burlap that had a plastic-like appearance. The fiber liner proved to be lacking in durability prompting its replacement with the resin type. The two types are visually different with the fiber type having a very thick rim and the resin type being much thinner.

Jacket

As a new design, the HBT Jacket (Jackets, Herringbone Twill, Specification No. PQD 45, dated 20 May 1941) was a radical departure from its predecessor (Coat, Working, Denim, Specification No. QMC 6-125B, dated 7 August 1940). Though both featured a coat-style front, the herringbone twill jacket had a very different appearance being made up in 8.5‐ounce olive‐drab herringbone twill material instead of the indigo blue denim used to manufacture working garments for the previous 20 years. Additionally, the new jacket was far more refined having detail not typically found on military work garments. These features included a finished bottom band with take-up straps and buckles, shirt‐sleeve style cuffs, rear yoke, shoulder pleats, and center pleat pockets with button flaps. In fact, the styling very much resembled that of a western denim jacket of the period.

Another novel feature of the herringbone twill jacket was its metal tack buttons. Instead of being sewn on, these buttons were attached by means of a tack that was pushed through the material into a hollow stem thereby securing the button to the garment. The design cast into the face of the button comes from the Great Seal of The United States. The design represents the original 13 colonies coming together to form a new nation and consists of thirteen small 5-pointed stars arranged in a pattern to form a single 6‐pointed star surrounded by light rays. Used throughout WW2 and the Korean War period, these buttons are commonly referred to as "Burst of Glory", or sometimes simply "13‐star" buttons. Button composition varied and included brass and steel alloy examples with various coatings. Early on, buttons were constructed in brass and had a light gray finish. Later, steel alloys were used to conserve brass and these buttons were typically finished with a dark black coating.

The HBT Jacket was a versatile garment. Being unlined, it was light enough to be comfortable in warm and hot weather where it could be worn over a light undershirt or by itself. Since the jacket was washable, it was often worn over woolen clothing in the field as a protective layer to save on dry cleaning costs. Its light weight and lack of bulk also allowed jackets and coats to be worn over it when needed.

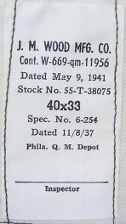

HBT jackets were manufactured in sizes ranging from 32 to 46 and were cut in both regular and long lengths. An ink stamp was applied to the inside nape area indicating the jacket's chest size and cut. A contractor's label was usually attached inside the right pocket that provided the contractor's name, contract number, date of contract, stock number, size, and specification number. These labels didn't last long and often disintegrated after a couple of washings.

For the enlisted man, the two‐piece HBT suit was part of his basic clothing allowance. Because it was an important part of early training that included drilling, field exercises, and fatigue duties, the outfit was used frequently and subjected to heavy wear. To reflect these circumstances, the Tables of Basic Allowances from the 1942‐43 period show that no less than three HBT jackets were included in the enlisted man's initial issue of clothing. Officers could also wear the HBT jacket for situations where protective clothing was necessary to spare regular uniforms from undue soiling. Unlike enlisted men, officers would normally be required to purchase this outfit. Officers are most often seen wearing HBT suits during field and training exercises, or in combat areas.

An updated specification was approved for the HBT jacket in January 1942 (Jackets, Herringbone Twill; Specification No. PQD 45A, dated 16 January 1942). To the casual observer, jackets bearing the new specification appear identical to jackets made under the previous specification. At the time of this writing, the exact reasons for the new specification remain unknown. However, it is likely that the new specification specifically allowed for the use of substitute standard materials. Empirically, jackets produced under PQD 45A generally exhibit substitute standard steel alloy buttons in lieu of the standard brass type. Additionally, some first pattern jackets and trousers of late production were made with herringbone twill material that was darker in color and exhibited a finer weave making the characteristic striping effect nearly invisible. Jackets made under specification PQD 45 were procured between 12 May 1941 and 30 January 1942 and jackets made under PQD 45A were procured between 19 February 1942 and 27 August 1942. Going forward, the HBT jacket would go through a major redesign during October ⁄ November 1942 (Jackets, Herringbone Twill & Jackets, Herringbone Twill, Special; Specification No. PQD 45B, dated 2 November 1942). This occurred in response to the two-piece suit being adopted as a hot weather combat uniform and the need to simplify manufacturing in order to increase procurement options.

Trousers

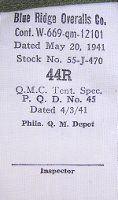

Like the hat, an existing design was used as the basis for the HBT trousers. This time, the khaki trousers were used as the model (Trousers, Cotton, Khaki; Specification No. QMC 6‐254, dated 8 November 1937). Initially, a specification was drawn up at the Philadelphia Quartermaster Depot for HBT trousers (Trousers, Cotton, Herringbone Twill; Specification PQD No. 42, dated 25 March 1941) that used the same pattern as the denim trousers in use at the time (Trousers, Working, Denim; Specification 6‐124C, dated 8 August 1940). However, the PQD 42 specification ended up not being used and instead the specification for khaki cotton trousers was amended to include the new HBT type (Trousers, Cotton, Herringbone Twill; Specification QMC No. 6‐254, dated 8 November 1937 with Amendment No. 1). The practice of utilizing the same specification and pattern for multiple items, whenever practicable, was a sound one that allowed procurement to proceed unhindered. For example, doing so allowed established manufacturers of the khaki cotton trousers to produce the new herringbone twill type without having to re‐equip or change their current assembly procedures. In addition, any new contractors, once equipped, could produce either product when the need arose.

Visually, the HBT trousers appear the same as the khaki cotton trousers except for the fabric and the type of buttons. The pattern used for these trousers was typical for the period being similar to civilian trousers and not too different from the enlisted man's wool trousers worn with the winter service uniform. Notable design features included internally hung side pockets with canted openings, internally hung rear pockets, and a watch pocket under the right side of the waistband. Flat felled, double stitched leg seams, typically used on denim jeans, were used for durability and to prevent the seams from splitting. The material was the same 8.5‐ounce herringbone twill used to make the jacket. The inside waistband was lined with 7.5‐ounce unbleached cotton drill as was the right side of the fly. Buttons were the same thirteen‐star tack type used on the jacket. The front opening used a concealed fly with the waistband button being exposed.

The jacket, trousers, and hat that comprised the HBT suit were all part of the enlisted man's basic clothing allowance. Like the jacket, three pairs of trousers were issued to the enlisted man upon entering service and reflected the critical role these garments played during training, field, and chore activities. HBT trousers could also be purchased by officers for wear in situations that would otherwise unduly soil other uniforms, such as field and training exercises and combat. In an interesting sidenote, first pattern HBT trousers were also procured by the US Navy for issue to ground personnel stationed overseas. Navy procured trousers were sometimes made with olive‐drab cotton twill instead of the usual HBT material.

Markings for size and a contractor's label were applied to the trousers. The size markings consisted of waist and inseam measurements that were ink stamped to the inside waistband above the right, rear pocket. On occasion, early production trousers had a linen size label tacked with thread on the outside above the right, rear pocket. A printed contractor's label was sewn to the front, right pocket on the side that faced away from the body. This label carried the contractor's name, contract number with date, stock number, specification number with date, and size. As the garment was laundered, the contractor's label usually became illegible and eventually fell off.

A couple of changes occurred to the HBT trousers during the life cycle of the QMC 6‐254 specification. The first involved altering the pattern of the trousers to improve the fit in the waist area and resulted in another amendment being added to the specification (Trousers, Herringbone Twill; Specification No. QMC 6‐254 with Amendment No. 2, dated 3 March 1942). These trousers were given a higher rise and the seat area was increased by two inches. The new pattern can be distinguished easily from the old by the distance from the rear pocket opening to the top of the waistband. Before the change, the rear pocket opening was located very near the top of the trousers just under the belt loops, and after the change, the pocket opening was set much further down (see photos above).

During the later stages of production, additional changes were made to the HBT trousers. In the fall of 1942, the two rear and watch pocket openings were changed from double welt to single welt openings in order to simplify the manufacturing process and reduce costs. Also, some trousers manufactured during this time had standard plastic buttons sewn to the fly instead of the usual metal tack kind. During November 1942, procurement of trousers bearing the 6‐254 specification came to an end and the common path that the HBT and khaki cotton trousers shared diverged with new specifications being issued for both types. Specification No. PQD 339, dated 12 February 1943 was issued for khaki cotton trousers in lieu of the 6‐254 specification and exhibited all the changes made heretofore under the old specification, including the simplified pocket openings. Going forward, the HBT trousers would sport an entirely new look as a result of the two-piece HBT suit being adopted as a hot and tropical weather combat uniform and the need to further simplify the design for mass production (Trousers, Herringbone Twill; Specification No. PQD 42A, dated 30 October 1942).

Undergarments, Overgarments & Misc Items

HBT suits were worn alone, under, or over a number of other garments depending on needs and climate conditions. The first pattern two‐piece suit discussed in this article is mostly seen being used for fatigue work or field exercises by enlisted men during basic training as was originally intended. In summer conditions, the suit was worn over the cotton white sleeveless undershirt and matching short white drawers. In very hot conditions or when used as a tropical combat uniform, the jacket was often worn with nothing underneath. Other times, in cooler weather, the standard enlisted man's flannel shirt can be seen underneath the jacket. During field training exercises, heavier garments like the olive drab field jacket or mackinaw coat were sometimes worn over the HBT jacket when required for warmth. When men were assigned to heavy work details, they were typically issued heavy leather gloves for protection. There were several types of leather gloves issued during the war depending on the job being done and mainly had to do with the length of the gauntlet and whether there was a tightening strap for the wrist.

Footwear

Unless engaging in work requiring specialized footwear, enlisted men wore the standard Army russet brown high‐top service shoe with the two‐piece HBT suit. The service shoe was an unlined, ankle high shoe made in a blucher pattern. The cowhide uppers were fully chromed and vegetable retanned. There was a toe cap with brouge holes and a rubber heel to help reduce wear. Early shoes had a leather outsole, but from early 1942 onward most had a rubber or synthetic rubber tap added. Still others had hobnails added to a double leather outsole. When required, any one of a number of different types of specialized army footwear could be worn with the HBT suit, such as rubber knee boots, waders, lineman's boots, etc.

During field exercises, canvas leggings were worn to protect the lower leg and keep debris out of the shoes and trousers. These were worn over the top of the shoe and with trousers tucked inside the top of the leggings. Made from heavy number 6 duck, the leggings were 12¾ inches high. They were held secure with laces that ran through a series of metal hooks and eyelets facing the outside of the lower leg. The bottom of the legging was secured to the shoe with a strap and buckle that fastened around the shank. Color of the leggings varied. Those made prior to mid‐1941 tended to be khaki color, and those made after this time were a light-green color designated olive‐drab shade 3.

Service shoes were worn with either light or heavy wool socks. In mid‐1942 a 50% wool 50% cotton sock with a cushion sole was introduced that replaced the heavy wool sock and eventually became the most common type of sock worn with the service shoe. By war's end protocol stated that either one pair of cushion sole socks or two pairs of light wool socks were to be worn with the standard service shoe.

Conclusion

HBT suits were, perhaps, the most ubiquitous uniform of the 1941‐45 period. The fabric was found to be very adaptable and served a number of purposes. As mentioned, it clothed soldiers for chore work, field training, combat, and mechanic work. It served as a flight suit, jump suit, jungle suit, and was an Armored Forces uniform. Since these suits were widely distributed and in continuous use, they were constantly going through design changes and modifications. As a result, there were perhaps more variations of these garments produced than any other type of uniform during the WW2 period. HBT suits were made in one and two‐piece designs, with camouflage prints, with light and dark shade olive‐drab fabric, with different pocket styles, varying pocket positions, with different button types, with special features, and impregnated for protection against gas attacks. Furthermore, in addition to men's types, the Women's Army Corps also issued HBT uniforms having their own unique designs. Lastly, both the Navy and Marines produced their own versions of HBT suits. There exists a vast array of HBT garments for the historian and collector to track down and assembling all the variations into a complete and orderly set can be a real challenge.

As versatile and important HBT was to the war effort, its use as a tropical combat uniform was intended only as a stopgap measure necessitated by the emergency of the time. In fact, by the end of the War, a uniform had been developed specifically for use in tropical combat conditions and was made in cotton poplin instead of herringbone twill (Jacket, Lightweight, Special; Specification No. PQD 523, dated 3 August 1945 and Trousers, Lightweight, Special; Specification No. PQD 524, dated 2 August 1945). Though HBT uniforms were replaced for tropical combat use, they continued to be used for training, fatigue, and in the summer combat role. In the spring of 1945, the herringbone twill jacket was redesigned to more resemble a shirt having its large, expanding cargo pockets replaced with much smaller shirt‐style pockets having no expansion pleats. The trousers reverted to a more traditional pocket arrangement by eliminating the side cargo pockets for two front and two rear patch pockets. In 1947, herringbone twill was officially replaced with cotton sateen. This changeover was gradual as large stocks of herringbone twill material continued to be used up. As a result, both cotton sateen and HBT uniforms appeared side‐by‐side for quite some time afterward. By the mid‐50s most HBT had been used up, thus ending an era of one of the most recognizable uniforms in US Army history.

The legacy of the classic WW2 two‐piece herringbone twill uniform lives on today. After the war, large quantities of HBT uniforms were sold into the surplus market and to this day still turn up in thrift shops, secondhand stores, flea markets, and the like. Furthermore, these garments were produced in such vast numbers during the war that many still survive in pristine condition. As a result, it's not too difficult for the collector to pick up a nice original example, especially in the case of one of the more common types. For living history enthusiasts, a number of companies around the world offer reproductions of the most common variations of the two‐piece HBT suit. In a lasting tribute, for decades the leisure wear industry has produced jackets and trousers for public consumption based on the classic WW2 herringbone twill design.