U.S. Army Men's Shoes

Service Shoes

Specification QMC 9-6F Dated 21 November 1941 (Type I)

Stock No. 72-S-1806-35 - 72-S-2173

Composition Sole Service Shoes

Specification QMC 9-6F Dated 21 November 1941 (Type II)

Stock No. 72-S-2223-20 - 72-S-2253-70

Two pairs of service shoes were issued to Army and Army Air Force enlisted personnel as a mandatory allowance. Type I and Type II Service Shoes were general issue items until early 1943 when other types of service shoes and boots were developed for overseas use. Thereafter issue of these shoes was to be confined to the zone of interior. Officers were required to purchase two pairs of shoes or boots suitable for wear in the field and could choose to purchase and wear the standard issue service shoe for this purpose.

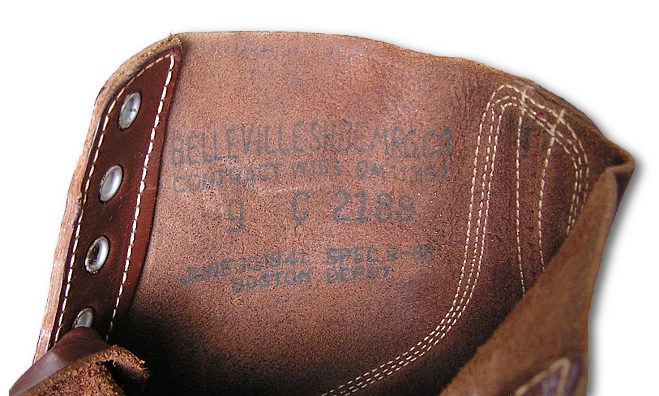

| Key Visual ID | Primary Materials | Fasteners | Color | Labeling |

| Top-grain, polished uppers. Toe cap with brogue holes  Brogues are small holes in the toe caps or wing tips of leather shoes. On commercial shoes they are sometimes arranged in decorative patterns. Originally they were to provide aeration when the leather became wet. . Type I shoe: leather outer soles. Type II shoe: composition outer sole constructed with leather and rubber tap. | Leather uppers and soles. Rubber, reclaimed rubber, or synthetic rubber used for heels and taps. | 40 inch laces strung through 7 to 9 pairs of metal eyelets depending on shoe size. | Army Russet Shade. | Contractor labels were ink stamped to the inside top of the quarters. Size tariffs are found embossed on the shank, on the insole, and with the contractor label. An inspector's stamp is usually found on the backside of the tongue. |

| Treatments | Approx. Contract Run | Preceded By | Replaced By | Companion Garments |

| A two stage tanning process was use for the leather uppers. The leather was chromium-sulfate tanned to improve water resistance and then retanned using vegetable tanning material. | Type I shoe: 5/2/41 to 12/9/1941. Type II shoe: September, 1941 to December, 1942. | Service Shoe, Specification QMC 9-35A (1933). | Composition sole service Shoe, specification BQD 75C (9-15-45). Composition sole service Shoe, specification QMC 9-6G (1948). | Olive drab service uniform. Summer service uniform. Fatigue uniforms. M-1938 olive drab dismounted canvas leggings. |

(touch or point with mouse for expanded view)

|

After WWI the service shoe changed from one designed for combat field use to one designed to optimally serve a peacetime army. By the late 1930's general purpose use, comfort, and good appearance were the hallmarks of the Army's service shoe. As war loomed on the horizon in the early 1940's, the US Army was in real need of a service shoe designed to cope with rigorous campaigning. It wasn't until premature shoe failures that occurred during pre-war field maneuvers that the Army began to take action. Once the US entered WWII, poor results from the early campaigns provided further impetus to develop adequate combat footwear. While development of a suitable field shoe was the main driving force for change, conservation of materials also played an important role in shoe development due to the tremendous pressure put on raw materials in trying outfit a wartime army. Despite all the developmental work that occurred around the service shoe in the war years, ultimately the Army decided upon a universal combat boot to outfit US troops in the field.

Service shoes of the late 30's were characterized by polished grain-out uppers, toe caps with brogue holes, and leather outer soles. These shoes were a stark contrast to the flesh-out, hobnailed type which finished out WWI. There were at least two types of shoes in use by the Army as the 1930's drew to a close. These shoes were similar in outward appearance, but one type, referred to as a service shoe, was unlined, had an outside counter pocket, and stacked leather heel; while the other, referred to as a garrison shoe, was a lighter type with fabric lined quarters, a rubber heel, and utilized lighter laces with smaller eyelets. The Army's light garrison shoe was similar to the high top service shoes the Navy and Marine Corps were using at the time. By early 1941 procurement of the Army's light garrison shoe and stacked heel service shoe ceased in favor of a heavier, unlined, universal service shoe that made use of a full rubber heel.

As the Army's manpower was built up, large scale field maneuvers were conducted in 1940 and 41 to prepare for the possibility of war. During these maneuvers it was found that the leather outer soles of the service shoe wore through in just two to three weeks. To solve the premature sole wear issue, a composition sole was developed in which a rubber tap was attached to the leather outer sole just forward of the shank. With this improvement, wear time of the sole was expected double under various conditions of use. Procurement of the new Composition Sole Service Shoe, Type II, began in September, 1941. Procurement of the type I shoe continued through December, 1941. The onset of war brought extreme pressure on the supply of rubber, leather, brass and other raw materials used in the making of service shoes. This situation brought about efforts to conserve these materials and by mid-1942 the Boston Depot introduced several modifications to the type II shoe (BQD Specifications 75, 75A, & 75B). Among the conservation measures taken was the reduction of the crude rubber content of the tap until it was made entirely of reclaimed rubber. Additional conservation measures included the use of lighter insoles, strip gemmingStrip Gemming - A method of shoe construction where the outer sole is glued, instead of sewn, to the inner sole via a strip of material, which allows the shoe to be produced quicker and cheaper., cork filler material, wood-core heels, and the use of zinc coated steel reinforcing nails. While intrinsically weakening the shoe, these modifications did not result any outwardly visible differences to the shoe. During 1941, the Army re-introduced a hobnailed service shoe. This shoe was the same as the type I shoe except that hobnails were applied to the outer sole and a stacked leather heel with either a steel rim or hobnails was used in place of the usual rubber heel. Though issued in limited quantities this shoe provided an alternative to the type I and II shoe where heavy wear was expected. Although solutions had been reached to extend the life of the service shoe while at the same time conserving materials, the shoes performance in the field continued to prove unsatisfactory. Early overseas use revealed a susceptibility to rapid deterioration when exposed wet and damp conditions. In mid-1942 projects were started at the Boston Depot to improve the water resistance of the service shoe while efforts also got underway to develop a combat boot. In the development of a combat boot it was hoped that such a design could be a universal issue replacing several types of specialized footwear and also enable the elimination of the canvas leggings that were worn with service shoes in the field. The immediate solution for improving the water resistance capability of the current shoe was to go to a flesh out shoe, as had been done in WWI. The flesh-out shoe, where the gain side of the leather now faces inward and suede side becomes the outside of the shoe, was decided upon because of the ability of the flesh side to absorb water proofing compounds. In addition to a rubber heel, the new shoe, designated Type III, would now sport a full rubber sole that extended over the shank (Composition sole Reverse Upper Service Shoe, BQD 110). As work continued on the conservation of materials, the crude rubber sole developed for the type III shoe would change over time to reclaimed rubber and eventually synthetic rubber. Procurement of the type III shoe began in January, 1943 as further orders of Type II shoe were halted so that industry could concentrate on producing the new field shoe. When deliveries of the type III shoe began in April they were to be reserved for overseas issue only, while existing stocks of type I and II shoes were now only to be issued in the continental US. In the summer of 1943, as final development of the combat boot took shape, changes were made to the type III shoe. At this time the toe cap and two reinforcing rivets located at the top of the back stay were dropped from the shoe. The effect was that the type III shoe was now the same as the combat boot except that the combat boot had a 5 inch leather cuff sewn to the top. These changes allowed for flexibility in production and procurement of footwear, as both shoe and boot could now be produced without having to retool industry. A manufacturer could produce either item by the inclusion or exclusion of the cuff at the top. In the winter of 1943 the double buckle boot was approved by the Army Service Forces for general issue. Beginning in January, 1944 industry concentrated on producing the double buckle boot in quantity, and though this was the case, the type III service shoe continued to be procured for Army, Navy, and Marine use up until the end of the war. |

The service shoe made its final appearance in the fall of 1945 with a brief issue of a revised type II shoe. Since industry had been concentrating on production of the combat boot and type III shoe for some time, eventually need arose for additional supplies of type II shoes for stateside garrison wear. Two types of shoes were developed by the Boston Depot to meet this need; one was the same as the type III shoe except that it used army russet shade, polished, grain out leather for the uppers; and the second was identical except that it made use of surplus rubber taps that had been originally used on the type II shoe instead of the full composition sole (Composition Sole Service Shoe, BQD 76C dated 15 September 1945). Massive war-time procurement left the Army with quantities of footwear to outfit new troops for some time. It wasn't until 1948 that service shoes were again needed and at that time a new shoe was introduced that mixed design features from both early and late war types (Composition Sole Service Shoes, QMC 9-6G, 1948). Like early war shoes, the new shoe had a toe cap and used highly polished, grain-out leather for the uppers. And like the later war shoes it made use of a full composition sole. Though a toe cap was used on the new shoe, it no longer had the brogue holes at the seam as had been the case during the early war years. The type I and type II shoes were the mainstay footwear for the enlisted US soldier during the early war period. These shoes were worn for training, garrison use, maneuvers, and overseas campaigning. In the spring of 1943 when the reverse upper field shoe was ready for delivery, the status of type I and II shoe was changed so that issue was to be confined to the United States. Every US Army inductee received two pairs of shoes as a mandatory allowance. This allotment was maintained as shoes wore out. Officers also wore the type I and II shoes in the field. When serving in a theater of operations, officers were required to purchase two pairs of approved footwear for this purpose. Officers could choose to purchase riding boots, service shoes, or commercial field shoes of approved patterns.

Service shoes were issued with a pair of canvas leggings that were worn over the shoe in the field. Leggings were designed to the keep dirt and debris out of shoes and trousers tucked in. They were held in place by lacing a series of eyelets and hooks on one side and then fastening a buckle and webbing strap that passed over the shank. Leggings were disliked by soldiers because they caused chaffing, were difficult and time consuming to put on, and the laces would often break. The double buckle cuff of the combat service boot was specifically designed to eliminate the inconveniences that the legging presented.

Tracing the evolution of the WWII service shoe is a difficult task due to the rapid changes occurring beginning in 1941 and continuing to the end of the war. Early on, development by both the Quartermaster Corps and the Boston Depot contributed to a confusing array of specification numbers that, at times, seem to appear randomly in shoes. Further compounding the situation is the lack of surviving examples of the various shoe types to examine. When a shoe sample is found, often there is no contract stamp or it is illegible. Because of these challenges, the history of the WWII service is likely to be an ongoing study. Evaluation of surviving examples, the Quartermaster Historical Studies published in 1946, and the Army Service Forces Catalogs of 1943 & 1946 appear to support the following development timeline:

Above left to right chronicles the outward appearance of the WWII era service shoe: Type II service shoe with toe cap and brogue holes (October 1942); Type III composition sole reverse upper service shoe with toe cap that lacks brogue holes (January 1943); Type III composition sole reverse upper service shoe without toe cap (February 1945); Composition sole service shoe without toe cap (October, 1945); Composition sole service shoe with toe cap that lacks brogue holes (Specification QMC 9-6G procured October, 1948). Many variations of the WWII service shoe can be found. After the double buckle combat boot was approved, many existing type II and type III shoes had cuffs added to them in order to fill out combat boot procurement shortcomings. Another variation that turns up are type II and type III shoes made with corded soles that are very similar to the kind used on Marine Corps and Navy field shoes. |