U.S. Army Men's Caps & Covers

Officers' Khaki Tropical Worsted Service Cap

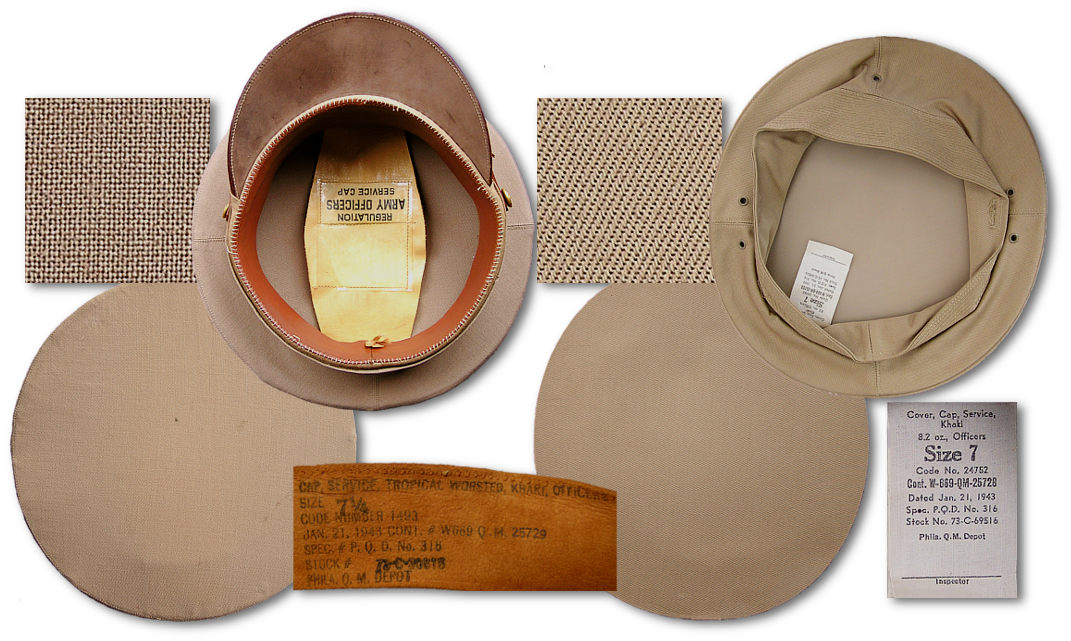

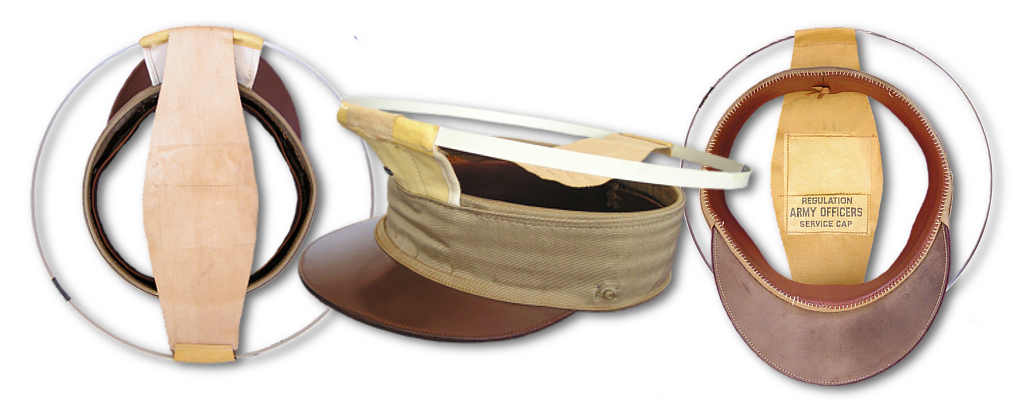

Above, left: Officers' Khaki Tropical Service cap with plain weave worsted wool cover. Above, right: The same cap is shown outfitted with the 8.2 ounce khaki cotton cover. Note the wire stiffener has been removed from crown of this cap; regulations allowed Army Air Force personnel to modify their caps to accommodate headphones.

Specification PQD 316 Dated 21 December 1942

Stock No. 73-C-30802 to 73-C-30826

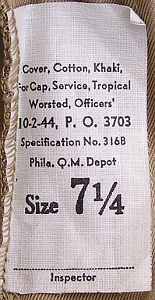

Officer's Khaki 8.2 oz Service Cap Cover

Above, left: Top and bottom of the worsted wool cap with inset close-ups showing the plain weave wool fabric and the contractor label that was stamped on the reverse side of the leather sweatband. Above, right: Top and bottom of the 8.2 ounce khaki cotton cover with inset close-ups showing the cotton twill weave fabric and contractor label found inside the cover. The khaki cotton cover was worn with the khaki twill shirt and trousers.

Specification PQD 316 Dated 21 December 1942

Stock No. 73-C-69510 - 73-C-69534

The summer service cap was an optional purchase for commissioned officers and warrant officers deployed overseas in temperate and tropical climate zones. It was also an optional purchase for officers and warrant officers stationed in warm weather areas in the zone of interior.

| Key Visual ID | Primary Materials | Fasteners | Color | Labeling |

| 1. "Regulation Army Officer's Service Cap" label on sweat protector. 2. Combination cap construction. 3. Contractor label inked to sweat band. | 1. 10.5 ounce plain weave tropical worsted wool. 2. 8.2 ounce khaki cotton. | Two 25 ligne (5/8 inch) gilt metal buttons located on each side of the cap frame. The buttons held the cap cover and chinstrap to the frame. | Khaki shade 1. | 1. The contractor label was ink stamped to the reverse side of the leather sweatband. 2. A size tariff was included in the contractor label and a small paper label was glued to the rear of the sweatband. 3. A "Regulation Army Officers Service Cap" label was ink stamped to the sweat protector. |

| Treatments | Approx. Contract Run | Preceded By | Replaced By | Companion Garments |

| Cotton khaki material was sanforized during its production process to reduce shrinkage during washing. | To date contracts have only been observed for January 21, 1943. | Unknown. | Service Cap Frame and Service Cap Covers Specification PQD 595 (1946). | Tropical Worsted Khaki 2-Piece Officer's Service Uniform; specification PQD 301, dated 12 November 1942. 8.2 oz Officer's Khaki Cotton Trousers; specification PQD 47A dated 30 November 1942. 6 oz Officer's Khaki Cotton Shirt; Specification PQD 98B dated 25 November 1942. |

Above, left to right: Top, side, and bottom views of the combination cap stripped of its cover and chin strap. A circular wicker frame served as the foundation that the cap was built upon. Khaki fabric covered the outside of the wicker band and a leather sweatband was attached to the inside. To form the front of the cap, a leather visor was attached to the bottom of the frame and a riser to the top. A wire stiffener was then looped through the top of the riser, and an oil cloth sweat protector attached to the front and rear of the wire stiffener.

(touch or use mouse to point at picture for expanded view)

|

In the fall of 1942 a new Officer's Two-Piece Tropical Worsted Khaki Service Uniform was approved for wear in warm and tropical regions. Specifications for the new outfit were drawn up at the Philadelphia Quartermaster Depot (PQD 301) and approved on 12 November 1942. In anticipation of the new khaki wool summer service uniform, revisions were made to the officers' olive drab service uniform lineup (PQD 149B dated 4 November 1942) by halting procurement of the light weight plain weave worsted wool versions of the dark shade coat and trousers, and drab (pink) trousers. With an appropriate summer weight wool uniform approved, a matching service cap would also be needed. Thus, specifications were drawn up at the Philadelphia Quartermaster Depot on 21 December 1942 for the Officer's Khaki tropical worsted service cap (PQD 316). Prior to the approval of the tropical worsted wool service uniform, the Philadelphia Quartermaster Depot had developed an officer's 8.2 ounce khaki summer uniform made of cotton twill. This uniform consisted of trousers (Spec. PQD 47, dated 21 April 1941) and either a stand-up collar shirt (Spec. PQD 98, dated 7 October 1941) or a convertible collar shirt (Spec. PQD 173, dated 1 May 1942). Specifications for these articles were revised shortly after the tropical worsted service uniform was approved. Changes included dropping the officer's convertible collar shirt and reducing the stand-up collar shirt from 8.2 ounces to 6 ounces (specification 98B, dated 25 November 1942). At the same time the officer's 8.2 ounce trousers were strengthened around the waist area (spec. PQD 47A, dated 30 November 1942). Revision of the cotton twill summer uniform was complete when an 8.2 ounce cotton khaki cap cover was designed and included in specification 316. The new cover would add versatility to the new summer service cap by allowing it to be worn with either the tropical worsted wool service uniform or the revised cotton twill outfit. The Quartermaster Corps decided on a combination cap design for the new officers' summer service cap. This type, used by the US Navy at the time, allowed the cap to be dismantled and various components changed including the top cover. The combination cap was a concept built upon a wicker head band that was set to a specific size. To form the front, a leather visor was attached to the bottom and a spring riser attached at the top. A 360 degree flexible wire stiffener, which provided form to the cap cover, was sewn into place at the top of the riser. An oil cloth sweat protector was attached to the front of the riser and looped around the back of the wire stiffener. Then a cover, cap band, and chinstrap could be placed over the frame to be held down with a button on each side. Regulations allowed Army Air Force personnel to remove the wire stiffener and the riser thereby allowing the cap to be worn with headphones. Sometimes only the wire stiffener was removed depending on the preference of the individual. It was a common occurrence for Army Air Force personnel to modify their service caps and was done not just for work requirements, but also for the "look" it provided. Modified caps are loosely referred to as "crusher" caps because of the collapsed and floppy appearance of the crown. Cap buttons were 5/8 of an inch in width and prominently displayed the US Coat of Arms. Composition consisted of a gilt metal facing mated to a backing that could made of any one of a number of different metals or even plastic. Some buttons used a screw and nut system to anchor into the frame. The nut had a short threaded throat with a flange at one end. The throat was pushed through the back side of the wicker frame and pinned into place through holes in the flange. Once the nut was secured, the button could be screwed in place from the other side. Still other buttons were held in place using a pair of flexible wires or prongs that protruded from the back side of the button. The prongs were pushed through the chinstrap, cover, and frame from the outside and then bent flush between the sweatband and frame. Officers' uniforms and caps often made use of buttons with the coat of arms design done in high relief. Though striking in appearance, high relief buttons were not always available, and as a result regular buttons can also found on officers' uniform equipment. Army regulations required that the officers' service cap emblem be a 2-3/8 inch high representation of the US coat of arms and be attached at the front of the cap. The badge was usually made of gilt metal and was attached via a screw post that passed through holes in the cover and riser and was then locked in place with a nut from the inside. Two straight keeper pins were located on the back side of the badge to help hold it straight. Many variations of the officers' cap badge existed. Some were attached to the cap by pin back instead of screw post; some were made of woven bullion wire instead of gilt metal; and many did not conform to regulations regarding size. Height ranged anywhere from 2-2/8 to 3 inches with just as much variation being found in the width as well. Artistic renditions of the coat of arms design also varied. Details of the burst of glory, eagle, and shield design was not controlled down to the minute detail, thus variation was great. See an example in the Details II section above. In the spring of 1942 the Army began a program whereby officers uniforms could be purchased at a discounted price. |

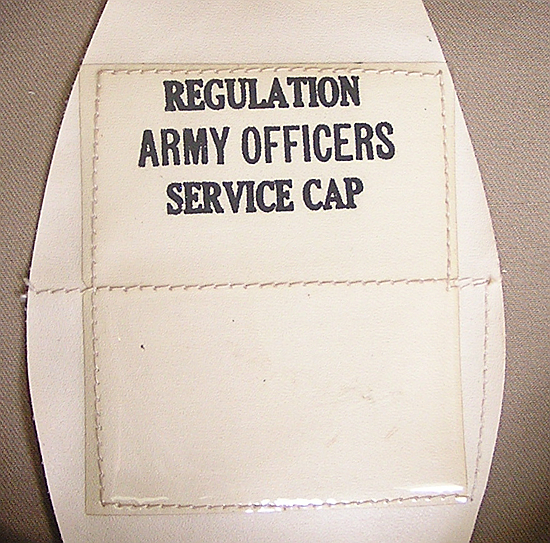

These uniforms were sold at post exchanges and retail outlets and carried a "Regulation Army Officer's" label on them. Army officers' service caps had this label printed on the oil cloth sweat protector and covered with a rectangular plastic shield. These caps also had a contract label ink stamped behind the leather sweatband. Contactor stamps can be notoriously difficult to read due to the fact they were applied to the flesh out side of the leather often resulting in a blurry stamp. Additionally, stamps were often applied with insufficient ink resulting in a faint or incomplete transfer. A size tariff was included with the contractor stamp and also applied to the back of the cap via a small paper sticker. As mentioned, specification PQD 316 also included an 8.2 ounce cotton khaki cover that could be used in place of the wool cover. Cotton covers came with their own contractor labels, which were attached to an inside seam. Studies of these labels show manufacturers produced both the finished cap as well as the auxiliary cotton covers. Both the wool and cotton covers had the braided cap band sewn directly to the cover eliminating the need for a separate cap band. The color of the braid was the same khaki shade no. 1 as the rest of the cover. The cotton cover was produced with a large circular plastic sweat protector sewn to the inside of the crown. Additionally, it came with a wire stiffener installed, which allowed the cover to be used with other types of cap frames if need be. The 8.2 ounce twill fabric, being a tight weave, required that the cover use two vent holes on either side to provide cooling. The loose breathable weave of the wool cover required no such vent holes.

In 1944 a modified 8.2 ounce cotton khaki cover was introduced (Spec. PQD 316B) with a redesigned sweat protector and clarified nomenclature. The new cover dropped the circular plastic sweat piece and replaced it with a treated frabic type that was now attached to both ends of the wire stiffener - the same type of protector used in the cap frame. Like the sweat protector found in the frame, the "Regulation Army Officers Cap" label was printed on its face. In addition to these design changes, the nomenclature was made more concise in how it described the cover. The new label read: "Khaki Cotton Cover for Officers' Tropical Worsted Service Cap". This helped identify the correct purpose and use for the cover.

The Tropical Worsted two piece khaki service uniform was designed to be worn by commissioned army officers and warrant officers. Either a service cap or a garrison cap made of like material could be worn with this outfit. Army summer uniforms could be made up in any one of several approved materials. Tropical worsted wool and cotton twill seemed to be the most commonly used. It was mandatory for officers to purchase summer service shirts, trousers, and garrison caps for wear when stationed in warm weather and tropical zones. Purchase of the summer service coat and peaked cap was optional. Army regulations dated 31 March 1944 state in regards to the wearing of the officers' summer service uniform; "The summer uniform will be prescribed by the commanding officer for wear when the climate weather requires it". Later, in regulations dated 31 October 1945 the above was clarified in regards to just the coat; "The summer coat is for optional wear. Commanding officers will neither require the purchase nor prescribe the wearing of this coat by officers of their commands." The Table of Equipment No. 21 dated 1 September 1945 lists the summer service coat and cap as an optional purchase for officers assigned to tropical zones or temperate zones during summer season. In summary, when stationed in warm and tropical areas, an army officer would have been required at the minimum to have a summer uniform consisting of trousers, shirt, and garrison cap. Summer service coats and peaked caps could also be purchased as optional items to be worn when authorized to do so. Not long after the war ended the combination cap concept was utilized to an even greater extent by the Army. In 1946 a new specification as drawn up at the Philadelphia Depot (PQD 595; Service Cap Frame) for a cap frame and accompanying covers that would supersede previous issues. The elastique, fur felt, and tropical worsted caps would all be dropped in favor of the combination cap consisting of a single frame to which various types of summer and winter covers could be attached. This article shows the tropical worsted cap developed and procured by the Army Quartermaster Corps during WWII. In addition to government procured caps, numerous others were produced by a variety of manufacturers and sold to Army officers at various retail outlets. In theory, these privately purchase caps were to conform to the US Army specification 316 shown here. However, some manufacturers adhered to published specifications better than others. Further accounting for the great variety of caps was the manufacture of caps made and marketed to Army Air Force personnel, many of which were of light weight construction and were without the stiffener and/or riser. |