U.S. Navy Men's Caps

Utility Cap Type N-3

Specification 73-C-5

The N-3 cap was part of a 4-piece utility uniform issued to U.S. Navy ground personnel. Recipients of the N-3 utility uniform included shore parties, construction battalions, amphibious units, combat, and security units. Utility caps were an individual allowance for personnel serving at overseas bases. Two utility caps were issued to eligible personnel assigned to bases located in temperate, tropical, or cold climates.

(touch or point mouse at picture for expanded view)

|

By the spring of 1943 the Navy had developed a new and improved line of special and protective clothing. Items were given an alpha numeric nomenclature of N-1, N-2, or N-3. The new issues included wool and wool lined winter wear, protective rain wear, and warm weather utilities. Special and protective clothing types were to be issued according to job function and weather conditions. Sizing was roomy allowing garments to be layered over one another in order to provide warmth, create a wind and water-proof "barrier", and at the same time allow flexibility of movement. New colors were introduced to provide better camouflage protection to forces deployed in combat zones. Instead of blue, black, white, and gray colors used in previous issues, the new garments would be either khaki, olive drab shade 7, or light green for items made of jungle cloth. Standard lists of outfits consisting of various "N" designated items were developed for issue to Navy ground personnel serving overseas in tropical, temperate, cold, and arctic regions. There was also a standard outfit list and allowance recommendations for personnel serving afloat. The utility cap was included in the list of items assigned the N-3 nomenclature. A list of N-3 articles and corresponding specification numbers follow:

Specialized and protective clothing could be issued either as an individual allowance or unit allowance. Unit allowances were calculated as a percentage of the compliment of a particular base. For example, at an aviation base it was generally recommended that enough "N" class articles be ordered to outfit 30% of the personnel. Utility uniforms were issued as an individual allowance to naval personnel serving ashore at overseas bases. The various components of the utility uniform were issued to the individual in the following quantities:

Utilities were issued in cold, temperate, and tropical climates. Some examples of units that received N-3 utility uniforms include Construction Battalions, Amphibious Forces, and Beach Parties. Prior to developing improved versions of its special and protective clothing, the Bureau of Yards and Docks was outfitting its ground personnel with Army herringbone twill designs. One-piece Army work suits and slightly modified Army two-piece suits were issued for chore work and hot weather field use. In 1943, the Navy approved a new multi-piece utility uniform to replace the Army types it was using. This time, instead of an Army design, the Navy patterned the new utility jacket and trousers on the Marine Corps' M-1941 utility uniform then in use. In addition to the jacket and trousers, both a lightweight broadcloth shirt and a baseball-style herringbone twill cap were developed to complete the new outfit. |

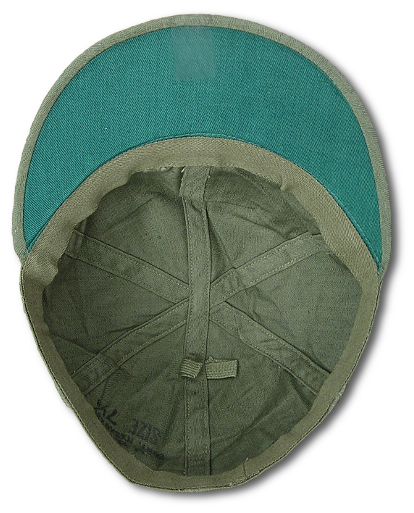

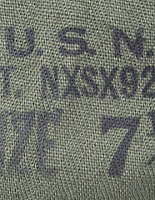

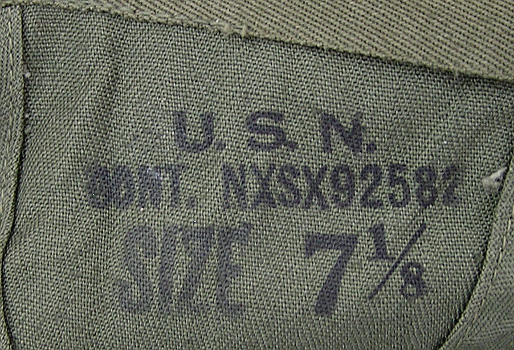

The Army's and Marine Corps' early HBT uniforms were, out of necessity, pushed into the combat role by the sudden onset of war. Evaluations of the early HBT uniforms led to improvements in subsequent issues. One area identified for immediate improvement was the need for better camouflage concealment in the jungle terrain of the South Pacific. In response, the Marine Corps opted to issue camouflage patterned utilities in 1942. After experimenting with a camouflage one-piece jungle suit in 1942, the Army approved the use of a darker shade of material in its standard HBT uniforms in the spring of 1943 . Though the Army continued to develop different types of camouflage uniforms, the darkened 2-piece HBT uniform would remain its standard issue hot weather combat field uniform throughout the war. At this time, the Navy also chose to produce their new utility uniform in the dark green olive drab shade 7 color. Army testing and reports from the field eventually revealed that a single dark shade of olive drab offered better overall camouflage properties in jungle environments than did various patterned designs. As a result, in the fall of 1944, 8.5 ounce, olive drab shade 7, herringbone twill material was standardized for use in Army and Navy utility uniforms (See joint Army-Navy specification JAN-C-154, Cloth, Herringbone Twill, dated 30 November 1944). The N-3 cap was very clearly modeled after the Army Air Force A-3 mechanics cap, which was already in full production by 1942. Visually similar in appearance, both were a six segment, baseball style designs that proved to be a very popular issue with servicemen. Made to be worn with the jacket, trousers, and shirt, the N-3 was constructed of the same 8.5 ounce, olive drab shade 7, herringbone twill material as its companion garments. The six segments of the cap were sewn together and reinforced on the inside through the use of HBT strapping. Heavy weight cotton twill was used for the sweatband, which was single stitched to the inside of the cap and reinforced at the front and back with an additional short span of stitching. A wide brim and the absence of any visor reinforcement stitching allowed the peak to be easily flipped up or down. The cap's flexible peak was a feature included in its general description and distributed in Navy circulars of the period. Wearing a cap with a flipped up peak proved to be quite popular during the war. Period photos often show the cap being worn in this manner. A piece of green hatter's cloth was used on the bottom of the visor to provide protection against glare. Two loops were attached to the inside of the cap on either side of one of the strapping seams that allowed the cap to be strung to a clothes line to dry using the standard Navy rope stops. Holes or loops for stringing uniforms to a clothes line were a standard built-in feature of WWII era Navy enlisted men's clothing. And while the N-3 cap had this feature, oddly, none of the other N-3 components, jacket, shirt, or trousers had any such provision. No identifying "U.S.N." ink markings were applied to N-3 caps as was usually done to the other components of the uniform. The cap's lack of any external marking is a quick and easy way to distinguish it from the very similar A-3 Cap, which had a heat transfer of the standard Army Air Force logo applied to one side. Size tariff and contract number was applied via ink stamp to the inside rear of the cap. An "NSX" prefix to the contract number identifies the cap as U.S. Navy issue. |