U.S.M.C. Men's Caps

Utility Cap

Model of 1944

Used to provide sun protection as part of the utility uniform as amended in 1944. Additionally, the model of 1944 utility uniform was designed to function as a hot weather combat uniform. For utility purposes it was worn by enlisted men during training and for chore work. In the field it was worn by both enlisted men and officers.

| Key Visual ID | Primary Materials | Fasteners | Color | Labeling |

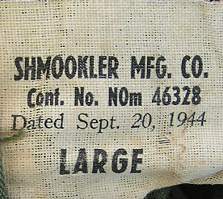

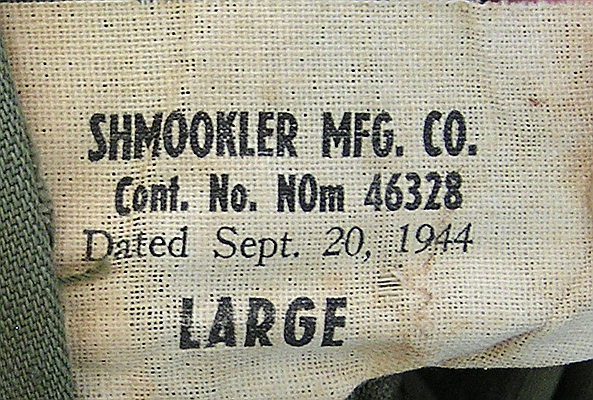

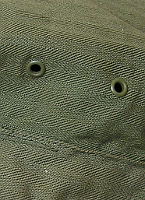

| EGA heat transfer on front crown. Length of visor. Absence of shaping dart on front of cap where EGA is located. | 9 ounce cotton herringbone twill. | N/A. | Unofficially referred to as light shade or sage green. Official color nomenclature unknown. | The contractor label was located on the inside rear of the cap, behind the sweatband. |

| Treatments | Approx. Contract Run | Preceded By | Replaced By | Companion Garments |

| Prior to assembling uniforms, HBT material was sanforized as part of the material manufacturing process to prevent shrinkage. | WWII manufacturing period: July 25, 1944 to June 7, 1945. This cap continued into to be produced into the Korean War era. | Herringbone Twill Cap, U.S. Army, Specification PQD 18B dated 8 April 1941. | Unknown. | Utility Coat Model of 1944. Utility Trousers Model of 1944. |

(hover for expanded view)

|

The Marine Corps utility cap came into being as a component of the revised utility uniform developed and issued in 1944. The new utility uniform was upgraded to include features to make it more useful in the field as a combat uniform. The previous HBT utility uniform, introduced in 1941, was developed along the lines of civilian denim chore clothing of the period. HBT uniforms were, out of necessity, adopted for tropical combat wear in 1942 for lack of time and any better alternative. Early on, the uniform was usually worn with a garrison cap or fiber sun helmet. But, soon after offensive actions began in the pacific, Marines were issued the Army's HBT mechanic's cap (U.S. Army Specification PQD 18B dated 8 April 1941) for wear in the field. A right facing EGA

Along with a new cap, the utility uniform took on a completely new look in 1944, with spacious cargo pockets being added to both the trousers and coat. Though similar in appearance to the previously used Army model, the new Marine's cap had some notable differences. The visor was made longer offering better shielding against the sun. Also featured was a ready-made EGA in form of a heat transfer, which was applied to the front of the crown. The location of the EGA affected the positioning of the shaping darts around the crown of the cap causing them to be arranged such that the heat transfer could be applied to an uninterrupted piece of material centered at the front. The positioning of the shaping darts around the cap are keys in distinguishing the Marine cap from the Army cap. M-1944 utility caps are sometimes found with the Marine's last name written boldly across the bottom of the visor. Caps marked in this way are encountered often enough to conclude that this was an approved ownership marking method. However, it is unclear whether this was a war-time or post-war practice. |

The coat and trousers components of the M-1944 utility uniform continued to be manufactured and issued according to specific chest and waist measurements. However, the cap was manufactured using a simplified sizing scheme; small, medium, large, and extra large. Owing to the generic sizing, ill fitting caps were commonly tailored at the rear sweat band seam to provide a better fit. Throughout the WWII period, the USMC continued to use a light shade of HBT for its utility uniforms. This color is often referred to as "sage green" by collectors and historians. It is unclear why the Marines continued to use this light shade HBT when developing the revised utility uniform in 1944; though it should be noted that separate camouflage patterned utility uniforms were also developed and issued alongside regular HBT utilities. In contrast, The Army and Navy darkened the color of their HBT uniforms to olive drab shade 7 in early 1943 in response to a call for uniforms offering better camouflage properties in the jungle terrain of the pacific. Then, as development of herringbone twill continued, the Army and Navy developed a joint specification for the material in 1944; JAN-C-154, Cloth, Cotton, Herringbone Twill, which called for 8.5 ounce, olive drab shade 7 material. In the fall of 1943 production of the Army's HBT cap changed over to the darker Olive drab color. This fact would have necessitated the Marine Corps' development of a HBT cap once the light shade of material was retained for the M-1944 utility uniform. The type of herringbone twill material used in Marine Crops WWII utilities seemed to have a distinctive appearance making them easily recognizable even at a distance. While color variations were common in WWII uniforms, and Marine Corps uniforms were no exception, the majority of Marine Corps light shade HBT seemed to have a more of a grayish cast than its Army & Navy counterparts. A more obvious difference occurred in the weave pattern. USMC HBT weave tended to have more pronounced ridges in the twill weave, creating a very discernible stripping effect. |