U.S. Army Men's Gloves

Heavy Leather Gloves

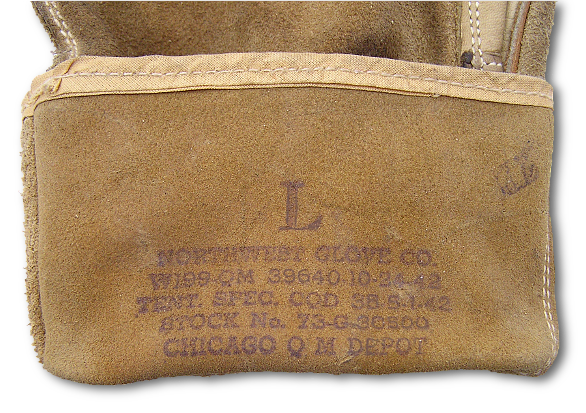

Specification CQD 38 Dated 1 May 1942

Stock No. 73-G-30500 - 73-G-30515

Heavy leather gloves were a discretionary allowance requiring the approval of the unit's commanding officer. The glove was distributed to men assigned to combat, combat support, combat service support, Army Air Force, and overhead and base installations. Distribution occurred in the zone of interior as well as in theater of operations located in all climatic zones.

| Key Visual ID | Primary Materials | Fasteners | Color | Labeling |

| 1. Straight shaft with no lining. Thumb seam strapping extending to the end of the shaft. 2. Absence of the short, lined wrist gauntlet/cuff present on the previous version. | Horsehide or cowhide. | N/A. | Natural tanned leather. | The quartermaster label and size tariff was ink stamped to the inside of the glove shaft. |

| Treatments | Approx. Contract Run | Preceded By | Replaced By | Companion Garments |

| Unknown. | Unknown; contracts have only been recorded for October, 1942. | Heavy Leather Gloves, Specification PQD 35A, dated 19 September 1941. | Heavy Leather Gloves, Specification CQD 38A. | Heavy leather gloves were worn along with various fatigue, utility, and field uniforms in the performance of heavy work. Composition sole safety shoes. |

(hover for expanded view)

|

Similar to civilian designs, the Army work glove of the WWII era was a robust design made in leather that offered maximum hand protection to workers engaged in heavy industrial type work where lighter gloves would be inadequate. Beginning in the late 1930's the glove went through a series of design changes that improved its strength and durability. But, as the Nation mobilized and then entered WWII, the heavy leather glove also went through a series of design simplifications and material changes brought about by the need to conserve scarce resources and meet greatly increased production requirements. The Army's WWII era heavy work glove has origins that date back to at least 1925 (see U.S. Army QMC specification 9-27; 1925; Gloves, Heavy Leather). Pre-war gloves involved a 3-piece design, made of horsehide, where a flesh-out top was joined to a top grain palm side and then a short gauntlet-like cuff was attached to protect the wrist. The outer edge of the cuff had an open seam that could be closed around the wrist using a short tab and pressure snap arrangement (see Quartermaster Corps specification dated 14 September 1939; Gloves, Heavy Leather). The side snap closure allowed the glove to be taken on and off easily, provided a snug fit when closed, and allowed ventilation when worn open. After 1939 the glove seams were strengthened and protected by utilizing welt construction and protective strapping. In the fall of 1941, just prior to the outbreak of war, a major reworking of the heavy leather glove occurred at the Philadelphia Quartermaster Depot. At this time the snap tab was eliminated from the wrist and the glove was strengthened by adding sturdy strapping to seams and leather coverings to the finger tips. The heavy leather glove was again reworked in the spring of 1942. This time changes were worked out by the Chicago Quartermaster Depot where additional simplifications and economies were implemented into the design. simplification was achieved by eliminating the short cuff that had been present heretofore. The cuff was done away with by simply extending the thumb piece and the top and bottom halves of the glove, thereby effectively extending the shaft of the glove to provide protection to the wrist area. Conservation of leather was achieved by utilizing split grain leather for the entire upper portion of the thumb piece. The small portion of leather on the palm side of the thumb remained top-grain. The heavy strapping that protected the thumb seam, introduced on the previous model, was continued and extended the entire lenghth of the seam to the end of the glove shaft. Sizes continued to be produced in small, medium, and large. |

Once the Army began its massive expansion in 1940, many raw materials came under pressure, and leather was no exception. The situation was compounded after the outbreak of war and it was during this time that several measures were taken to alleviate material shortages and expedite increased production demands. With horsehide in short supply, a cowhide tanning process was developed giving the leather many of the same characteristics of horsehide, and before the war ended cowhide became a standard material for heavy leather gloves. In the end, the final war-time variant would be limited to just two sizes; medium and large (See specification CQD 38A with amendment 4, 1943, Gloves, Heavy Leather). Heavy leather gloves were issued throughout the Army and Army Air Force organizational structure, primarily to men engaged in industrial type work, such as heavy lifting, construction, stevedoring, loading and unloading. Men requiring the use of protective gloves were typically attached to units such as maintenance and equipment companies, railroad and railway shop battalions, port stevedore sections, and boiler and smith shop companies. The nature of these jobs often required that many types of safety and protective clothing be issued. For example, in addition to gloves, one-piece work suits, safety shoes, specialized aprons, and the like could be issued. Specialized types of clothing were considered a discretionary issue, thus requiring the authorization of a unit's commanding officer. Further study of the development of the heavy leather glove is required due to the nature of the item and its relatively low survivability rate. There were at least three specifications written just prior to the U.S. entry into the war (1939, 1940, and 1941), and another two specifications written up by the Chicago Quartermaster Depot during the war (CQD 38 and 38A). Furthermore, the 1940 specification included multiple types. As more examples are uncovered and studied, this article will be updated. |