US Army Men's Hats

Rain Hat

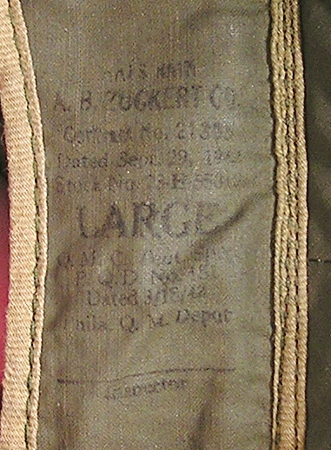

Specification PQD 151 Dated 18 March 1942

Stock No. 73-H-55010 - 73-H-55025

Primary Issue: Mandatory allowance for enlisted men, officers and warrant officers in organizations such as rescue boat squadrons, mine planter dervices, coast artillery, marine transportation, amphibious truck & armor, & port repair teams. Discretionary issue for all other personnel.

| Key Visual ID | Primary Materials | Fasteners | Color | Labeling |

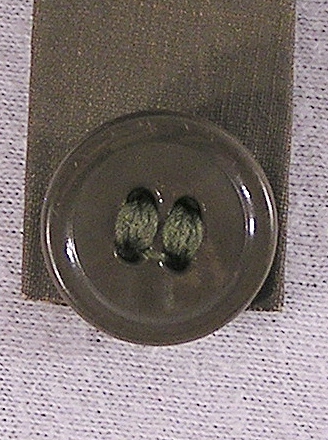

| Look for a general appearance resembling the U.S. Navy foul weather hat, but with the distinctive olive drab color of the Army. | A synthetic resin coated material was used for the outer shell. Flannel cloth was used for the inside lining. | One button was located on the right chin strap. Some examples used pressure snaps. | Olive Drab Shade 7. | The quartermaster label was ink stamped on outside edge of protective neck flap. The size was indicated on the quartermaster label. |

| Treatments | Approx. Contract Run | Preceded By | Replaced By | Companion Garments |

| Synthetic resin coating developed from limestone, coke, and salt by B.F. Goodrich Co. The treatment was commercially known as Koroseal and was used to waterproof and stain proof materials used to manufacture tablecloths, rain wear, shower curtains, etc. | Contracts have only been noted for July 29 & 31, 1942, but manufacturing likely spans a greater date range. | Rubberized Hat Spec. PQD 91. Rain Parka Spec. PQD 53 & Rain Trousers Spec. PQD 51. | Immediate replacement: Rain Hat Spec. PQD 151A. Spec. PQD 151 & 151A rain suits were replaced by the Wet Weather Parka & Wet Weather Trousers Spec. PQD 288A | Rain Jacket and Rain Trousers Spec. PQD 151. |

(hover for expanded view)

The rain hat was part of a three-piece wet weather ensemble that also included a pair of trousers and a jacket. All three pieces were encompassed within specification PQD 151 and were issued as a unit. The specification 151 outfit took advantage of a new synthetic resin compound in its construction, whereas previous rain gear utilized a rubber coated fabric. Under development for some time, the new material was adopted just in time to help offset critical shortages of rubber caused by severe war time demands. Complete satisfaction was never achieved with the synthetic compound, so debate went on throughout the war as to what construction methods should be employed to maximize its effectiveness. As a result, trial garments were produced using several different methods. Fabric was produced in which the resin coating was applied to one or both sides. Construction occurred by stitching or gluing seams together and utilizing rivets in various locations. In the end, manufacturing difficulties, material procurement delays, and conservation pressures mostly limited the application of the resin coating to one side of the material. The Quartermaster General, after satisfactory testing, deemed the one sided resin application acceptable when garments were constructed with the coated side facing toward the body and the textured fabric side faced away from the body. As a result, most synthetic coated rain gear was produced in this manner from mid-1942 through the end of the war. It is unknown how many different construction methods were used in the manufacture run of this hat. The sample hat shown on this page was made up using single coated material with the untreated fabric side facing outward. Seams are double stitched with the back side of the seams having a glued on fabric overlay known as strapping that was used to improve waterproofing qualities. | The brim of the hat was double textured, meaning both sides exhibited an uncoated fabric side. This was accomplished by joining two sheets of fabric together with coated sides facing one another thus leaving the fabric sides outward. This particular hat is easy to identify with its Navy influenced sou'wester styling and olive drab color. The wide brim, elongated in back, worked with the jacket's close fitting collar to keep rain out. Multiple piece rain suits were numerous in the war years. The Specification 151 suit was preceded by a rubberized parka-style set that included a hooded, zip neck, pull-over top and a simple set of drawstring trousers. When the Army replaced the Specification 151 rain suit, once again, a hooded, pull-over, parka-style design was utilized. This time, though, it featured a buckle neck opening, overall style trousers, and resin coated material. The specification 151 rain suit was similar in appearance to the U.S. Navy foul weather suit except for its color. Respectively, the Army and Navy typically followed similar patterns in their wet weather clothing development. Wet weather suit combos were generally issued to troops whose primary job functions were likely to expose them to wet and/or foul weather conditions. The multiple piece construction was essential in allowing freedom of movement and protection from wet conditions while performing essential job functions; an important distinction when issuing rain suits opposed to the standard raincoat. Port workers, amphibious units, marine transportation units, and the like would have been issued these types of multi-piece rain suits. |